How does Adidas use RFID to work in the fitting room?

Nov 15, 2021

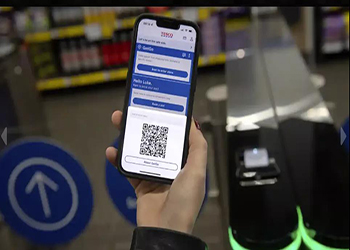

Recently, Adidas' first RFID smart fitting store in the Asia-Pacific region officially debuted in Shanghai. It is understood that this is the first RFID store built by Adidas in China and the Asia-Pacific region: With the automatic identification technology of RFID electronic tags, customers can personally feel the magic of RFID smart fitting rooms. Eachproduct ( cloth ,shoes ,hats ..etc ) ,they insert rfid tags ,some are 13.56mhz nfc sticker , some are 860-960mhz uhf sticker or tags according to different applications and reading distance .ZhiJie IOT Application Co.,Ltd with more 10 years rfid sticker label manufacturing experience and can provide different kinds of rfid chips products ,such as rfid label , on-metal or normal rfid tags , rfid wristband ,etc . After the customer enters the fitting room, the clothing will be automatically identified and displayed in the RFID fitting mirror, and different sizes and colors can be changed through human-computer interaction, and the fitting experience can be improved under professional advice, bringing customers a high level Retail innovation and digital service experience. With the increasingly fierce offline competition in the footwear industry, working hard on interactive applications has become a major innovation that businesses focus on. 1-RFID is becoming more and more popular in the field of shoes and clothing In fact, the application of RFID technology in the field of footwear and clothing has a long history. The well-known brands such as Decathlon, Nike, Adidas, Zara, Uniqlo, Hailan Home, etc. have already introduced RFID technology in their operations to improve their design, production, and logistics. The digital level of supply, retail services and other links. With the development of technology and the continuous maturity of scene applications, RFID has been applied in major links such as clothing design and production, warehousing and logistics, terminal retail, and washing services, and has become an important technology to promote the digital transformation of the clothing industry. The introduction of RFID and other digital management methods has not only greatly improved the production and operation efficiency of the footwear industry, but also made the brand's business strategy more flexible. Although the application of RFID in the field of shoes and clothing is not uncommon, most of the active applications are international brands from overseas. They generally have more than ten years of history in the application of RFID and have accumulated a lot of application experience. In this process, RFID has gradually played more value from the simple inventory efficiency improvement from the beginning. In comparison, domestic brands are more cautious in RFID applications. On the one hand, they are subject to the cost of RFID system construction. On the other hand, because of the scarcity of successful cases in the domestic market, brands dare not rush to roll out applications. . However, ...

view more