-

Tel : +86(0)755 21013852

-

Email : info@zjiotech.com

Tel : +86(0)755 21013852

Email : info@zjiotech.com

“So in 2019, we launched the RFID implementation project in the Itu distribution center as an initial pilot of our global RFID project. Currently, 100% of the vehicle clutches sold by ZF Aftermarket are shipped with RFID. This accounts for about 100% of our current sales. 20% of all products."

The RFID technology used by ZF is GS1 compliant with the aim of making this project a global strategic initiative. Silva said: “We are using GS1 compliant technology and we have seen an 18% increase in the efficiency of receiving operations. These parts are identified by the company’s clutch manufacturing plant in Araraquara. After integrating these parts and In the receiving process, our efficiency has increased compared to the traditional system.”

ZF plans to expand this RFID project beyond the Itu distribution center. “We hope that by 2022, 100% of products can be identified by RFID technology. The idea is to connect the entire supply chain from the factory to the customer. This way the customer can start from the moment the product is received from the technology. Benefit from the fact that there is no need for manual inventory, but automatic identification directly via RFID, which not only saves costs, but also has complete reliability.”

ZF wanted to go a step further and connect the entire supply chain to customers, enabling them to manage their inventory to enable automatic product changes and guarantee maximum availability. Silva said: "ZF is very bullish on this project, and Itu Brazil is a pilot for one of our projects with global reach. ZF's idea is to apply RFID to all of its global operations to bring value to customers."

Silva also said that before the project started, ZF wanted to find viable solutions for its many types of products. ZF Aftermarket's product portfolio is very broad, from clutches (the first product to implement RFID technology) to brake pads and small products containing large amounts of steel, rubber, brake fluid, etc., all of which require automatic identification. "That's why we were looking for an ally who could develop viable solutions for our different types of products." So Avery Dennison was involved at the beginning of this project.

“What makes Avery Dennison different is that it is a global company. We cannot work with suppliers who only work in Brazil, so solutions jointly developed in Brazil need to be globally applicable. For suppliers with technical capabilities It is imperative for business owners to be involved in developing and overcoming the challenges posed by a technology that, while not new, is unprecedented for the scale of applications that ZF is working on."

ZF Aftermarket ships a large number of parts every day. With 150 to 200 tons of material in circulation every day, the company serves approximately 750 sites throughout South America, shipping from Itu to ZF's distribution centers in Buenos Aires, Argentina and Cali, Colombia

As Silva said, ZFAftermarket is one of the major players in the replacement parts market and is positioned as a provider of mobility solutions far broader than the auto parts segment.

Fabiana Wu, RFID manager for Latin America at Avery Dennison Smartrac, said participating in ZF's project faced huge challenges because it was not an ordinary application. “We know that the use of RFID is the norm in industries such as apparel retailing. But in the auto parts industry, with a wide variety of materials, such as rubber and metal, and the high density within the pallet, we had to figure out which product would be the best fit for ZF’s need."

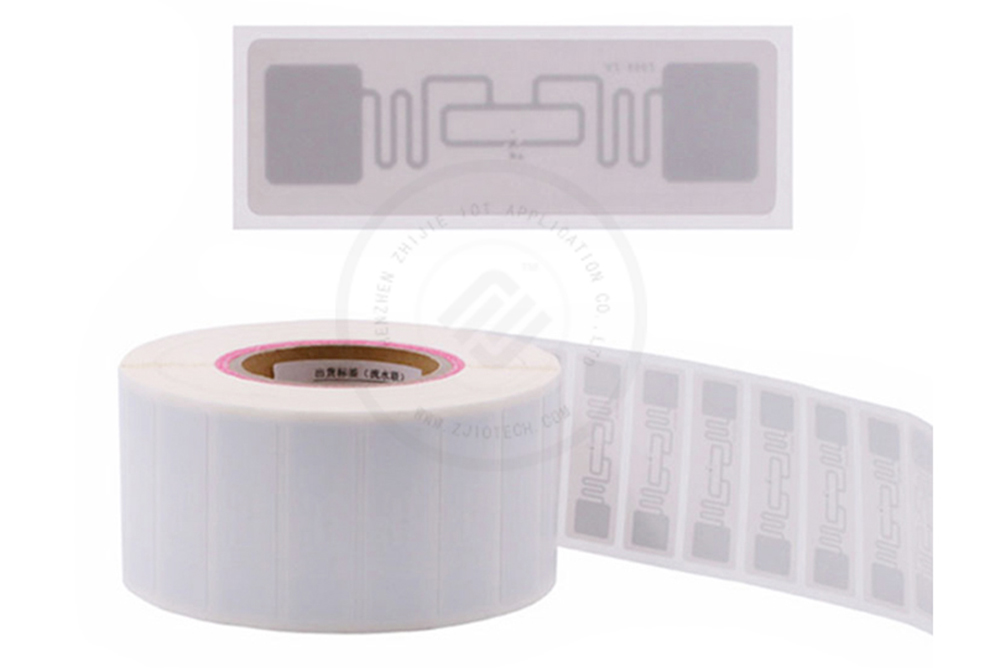

“It has been a valuable learning experience for the company, not only in finding the right inlay, but also in how to do it. We have support from ZF and its integrators as well as our international team.” She Explains, “In this project, we looked for an inlay-based solution that would have good readability no matter what product it was attached to. For this, we used more recent inlays that were not yet on the market. ZF Special inlays can be used, and no matter what material the label is placed on, we always try to use a legible inlay and simplify the process without losing authenticity.”

AveryDennison Smartrac works with integrators, Fabiana said. "We are not an integrator, it is the customer who defines the partner company." In this case, ZF chose an integrator who could support it. Avery Dennison worked closely with the integrator to find the best solution and best design for ZF to get the most out of the solution adopted.

Talking about what makes ZF's collaboration with Avery Dennison a special achievement, Fabiana said: "I believe a big difference for us is having the support of a global team, experimenting with Avery Dennison outside of Brazil. room, as well as the automotive industry experts who help us with tips and advice.”

"I would say that this project is still in the early stages and has a long way to go with ZF. However, I am optimistic because I feel that this project will be more successful, considering it as a whole, from here, in Brazil 100 % to implement it and try to implement it in the rest of the world.” Fabiana has a message to the market: “RFID is a trend, this technology is making progress and will open many doors to improve what we are already doing today. "

Thiago Cergol, strategic account manager for RFID at Avery Dennison Brazil, recalls that the project originated from ZF's interest in RFID technology for tracking and receiving products from its aftermarket product line. And Avery Dennison quickly provided a complete portfolio of all commercial products and labels for testing. “We worked with the technical team to provide inlays of different densities and sizes for a variety of different types of applications to meet the needs of this product line. For Avery, the partnership with ZF allowed us to do some testing to understand the automotive product relationship with the production environment.”

Finally, Cergol said: "Our goal is to achieve higher performance scores using the Avery Dennison Smartrac inlay on ZF products. Equally important, we would like to thank ZF and our converter customer Tecnoprint for their collaboration on this project."

Of course , how to implent RFID solution into car auto parts manufacturing tracking we also need to consider many points ,such as auto parts material , temperature during manufacturing , chemical panting , etc . For normally plastic auto parts we can use suitable size UHF inlay and adhesive backing for identifing and tracking processing , another metal auto parts even needing to assembly under high temperature and chemical painting we can use ceramic or high temperature PCB or industrial plastic over rfid chip and antenna then can make them good working peformance . UHF rfid products have good longer reading distance and high sensitivity , it shortly save time and many labors to inspect or tracking each procedure when car factory from assembly to wiedling even painting .ZhiJie IOT Application Co.,Ltd can provide our customers different kinds of UHF rfid products with different applications .

Statement : Pictures above only show the product , the intellectual property rights of the logo owned by their trademark