-

Tel : +86(0)755 21013852

-

Email : info@zjiotech.com

Tel : +86(0)755 21013852

Email : info@zjiotech.com

The Cat M1 cellular IoT technology involved here feeds the data to the cloud, while the UHF RFID tag data is read by a handheld reader.

Bartle Frere Bananas is a 30-year-old family-run banana producer that spans generations. The company produces around 250,000 15kg boxes of fruit a year, 60 per cent of which is supplied to grocery chain Aldi, with the remainder distributed to food retailer Woolworths, retailer Coles and an open market for dealers to trade fruit independently.

This banana growing farm is located near the Great Barrier Reef in Australia. The Great Barrier Reef, the largest and longest coral reef in the world, is highly vulnerable to pollutants run off from agricultural land.

Bartle Frere Bananas explained that the company's mission is to grow the fruit sustainably and to protect the local surrounding environment, including coral reefs. To implement the sustainable plan, it participates in a federally funded program called the Australian Government National Land Conservation Program, and has also received funding from Hort Innovation, the Australian Horticultural Innovation Association, to measure nitrate and soil moisture to track the condition of their farms.

The company then took it a step further - launching an RFID pilot to track fruit throughout the supply chain. All collected data is managed by Hitchi's Lumada Manufacturing Insights software.

The deployment of this project started with the implementation of IoT sensor technology at the plantation. Bartle Frere Bananas contacted Hitachi Vantara in early 2020 to install drainage sensors to monitor nitrates in sediment discharged from the plantation site. Nitrate sensors track not only irrigation but also fertilizer usage in each growing area; solar sensors use edge computing technology to monitor and report nitrate levels in operational pipelines that flow through river systems into the ocean.

This is part of the federal government and data-driven smart farming grant program.

The IoT system includes humidity sensors that detect irrigation levels, when more watering is needed, and whether there is a risk of overwatering. Up to six sensors are connected to a gateway node, which transmits data to the software over a Cat M1 cellular connection.

Currently, the system notifies Bartle Frere Bananas when the irrigation system needs to be turned on, but the actual control of irrigation will eventually be automated, said Owen Keates, head of manufacturing practice at Hitachi Vantara.

When it comes to nitrate management, Bartle Frere Bananas is minimizing this pollutant by providing crops with the ideal amount of fertilizer they need. “The data already shows that our practices are working,” says Devani. Lumada Manufacturing Insights software uses artificial intelligence modeling and analysis to predict when bananas will ripen, reduce the amount of pesticides that deviate from their intended targets, and determine ideal water usage. He can also watch the monitor and access the software to get a real-time view of farm conditions as well as recommendations.

Next, the company started tracking the supply chain. Typically, green bananas are gas ripened after being picked to ensure they are fresh and ripe enough to arrive at the store. "Keeping bananas as fresh as possible, from harvest to sale, is particularly important and challenging," says Devani. On the one hand, bananas have a limited shelf life and the amount of money they spend in the supply chain or distribution center. The longer it is, the less fresh it is in the store."

On the other hand, if the temperature deviates from the optimum temperature range of 14 to 16°C (57 to 61°F), the quality of the bananas may suffer. "You have to manage this process very carefully so that the fruit people buy is as fresh as possible," explained Devani. "Without RFID or other technology, once the bananas leave the company, the company can only trust the supply chain process."

Devaney sees the benefits of RFID in reducing the challenges of delivering fresh fruit to stores while providing more information to customers consuming bananas.

Bartle Frere Bananas seeks transparency and traceability from the banana plantation to the consumer, thereby enhancing consumer confidence. Transparency helps customers access Bartle Frere Bananas products. "Not long ago, a man bought bananas at an Aldi supermarket. The customer was so impressed with the taste and freshness of the bananas that he asked the store manager where the bananas came from. After learning the source of the fruit," Devani pointed out. , he called Bartle Frere Bananas wanting to buy more banana products and asked about where to buy bananas in the future. People want to buy your bananas, but they don’t know which bananas are yours. So we want consumers to know.”

So far, the RFID system has been used as part of the pilot. It starts with a banana plant, where the farm wants to track the chemical treatments provided at each location, and then link that data with each banana bunch as it moves to the store. Passive UHF RFID tags encoded with a unique ID number are attached to a bag that is wrapped around the banana bunches before they are harvested. The ripening gas that overflows inside the bag helps the bananas ripen.

Employees use hand-held readers to look up the ID of each banana bunch tag and associate the GPS-based location with those bananas in the software. Tag IDs can also be linked to other details such as fertilizer applied to the plant, irrigation data that planted the part. After harvesting the bananas, read the tags again to create date data in the software for that harvest event. The labels are then read again as they are sorted and packed in cartons. The temperature-controlled containers used to deliver the fruit to the distribution center are associated with that ID number, Kitts said.

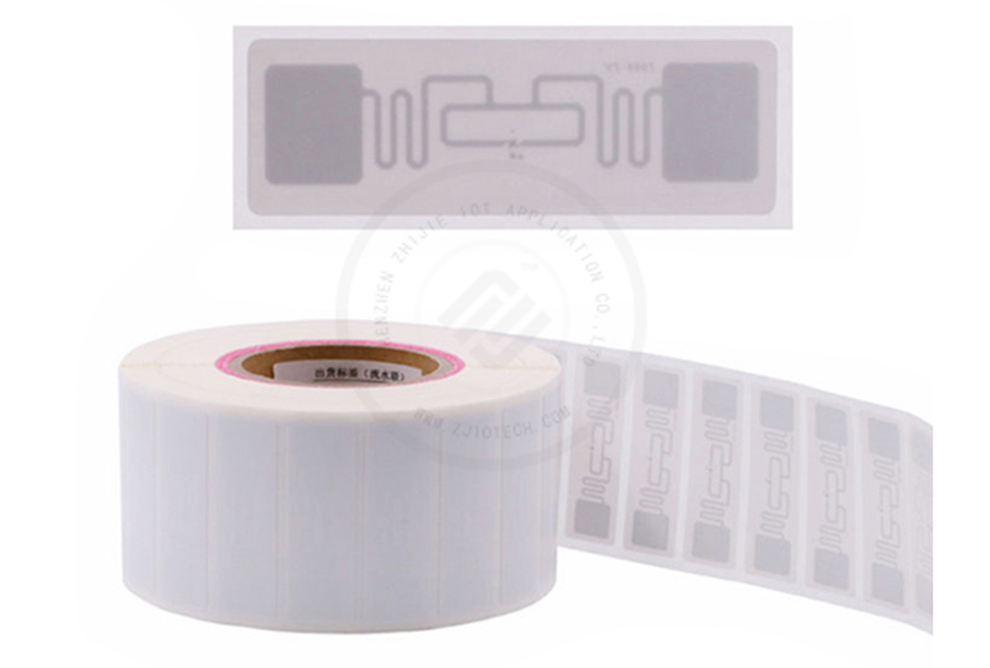

This kind of rain uhf tag has unique TID each piece and adhesive backside , we paste them on each banana bags or boxes then use UHF reader can scan easy and quick match thire ID , Shenzhen ZhiJie IOT Application Co.,Ltd has more 10 years experience in rfid products manufacturing ,can provide many kinds of rfid products such as rfid card , rfid label , nfc wristband , rfid laundry tags ,temperature sensor with nfc chip ,etc . Now more and more applications with rfid technology , espcially in plant management , animals ,medical and warehouse management . Using custom uhf rfid sticker label in banana management , save much more labor and gurantee each products are good qualify from plant , haverst until to supply chain

Bananas can be transported 2,000km to Sydney, or 3,000km to Adelaide, South Australia. To manage the conditions, Bartle Frere Bananas applies IoT devices with GPS trackers, LTE connectivity and temperature sensors from Hitachi Vantara in the reefer containers. When a connection is available, the device transmits updates about temperature levels every 30 minutes, and all data is uploaded when the device arrives at the distribution center.

Hitachi Vantara has been providing smart farming solutions for many years, starting in Japan. Its technology was first deployed to cattle farmers in Australia, helping to digitize farms, letting farmers know how much water and pasture is available, while tracking cattle movements. Hitachi has been working with the National Land Conservation Program to help farmers create smart, sustainable farms. In the future, it hopes to work with Bartle Frere Bananas to put RFID tags on each carton label to further track its products all the way to supermarkets.

Kitts said the data collected provides complete food safety, so if a problem with the fruit is found at the store, the farm can easily trace the shipment back to its origin. The information extracted from the RFID tags can also prove the integrity of the bananas, so the bananas can be sold as a premium product rather than at a discount. He added that as food moves from cultivation to market to consumer, these labels provide data to verify that each banana is produced to high environmental standards.

In the long run, the project deployment targets tracking and transparency from farm to consumption, which will support consumer confidence. "I want to get the pilot done so we can consistently do what we're doing, and at the end of the day, I want the marketing giants to understand that this stuff can work all the time, like it's done in the beef industry," Devaney said. like that."

Devani's vision is that grocery shoppers will eventually be able to scan a QR code on a banana and determine which family farm the banana came from. This information can be provided through data captured by RFID and IoT technologies. Scanning the QR code takes customers to Bartle FrereBananas' proprietary website, where they can browse the site, watch videos, provide feedback, and get information on how the bananas are grown. "

Statement : Pictures above only show the product , the intellectual property rights of the logo owned by their trademark